Course Materials

Course Objectives

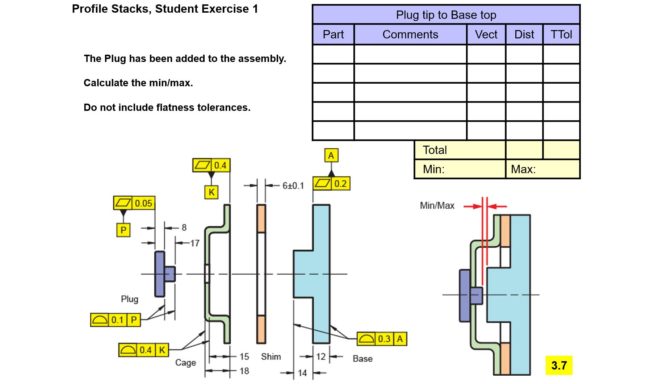

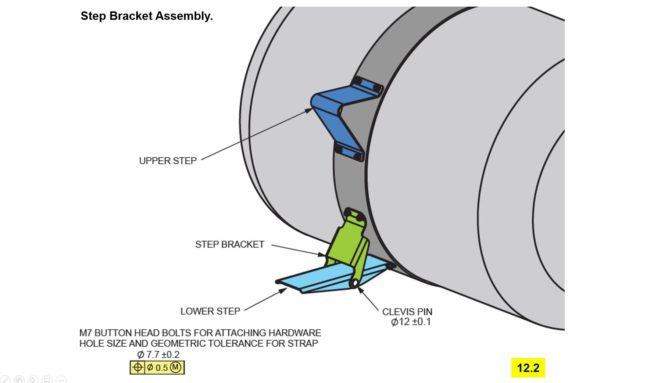

Students learn to apply geometric tolerancing on parts and assemblies in this advanced GD&T training. They will also learn to perform linear, axial, orientation tolerance stacks, and GD&T tolerance analysis to ensure functional requirements are met. After the stacks, reallocation of tolerances may be needed to meet manufacturing capabilities using worst case and RSS statistical methods.

Prerequisite: GeoTol Pro GD&T Fundamentals Course

Targeted Audience:Design engineers, drafters, manufacturing engineers, quality engineers and others involved with the creation of drawings, tolerance analysis, or design review.

Course Highlights

- Course Developed and Refined for Over 25 Years

- High-Level Design Course Using Case-Study Examples

- Learn Tolerance Stacks and GD&T Application in the Same Course

- Customizable Content for Focused Training

- Beyond the Theory with Relatable Examples and Practical Student Exercises

- Wood and Plastic Models Used for Demonstration

- Follows Along with GeoTol Applications and Tolerance Stacks Workbook